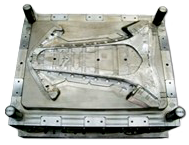

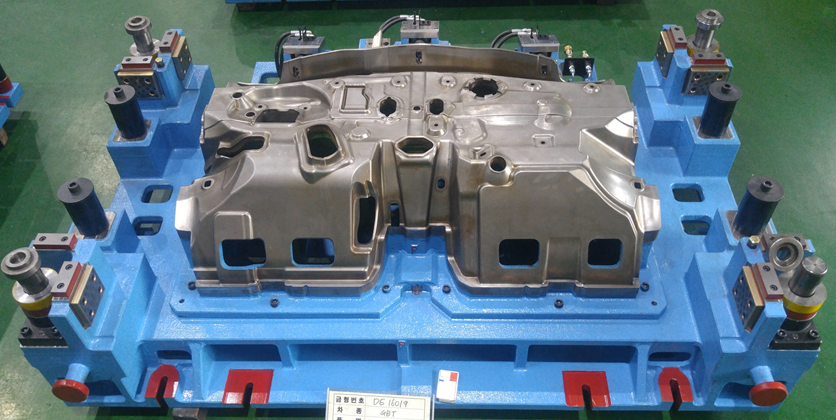

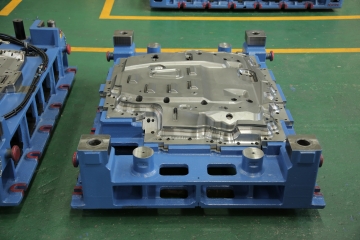

Design and manufacture the special molds for automotive interior parts and NVH parts. Types of molds include Hot forming molds, Cold forming molds, Steam forming molds, Foaming molds, Vacuum forming molds, and Insert molding molds.

Design and manufacture the special molds for automotive interior parts and NVH parts. Types of molds include Hot forming molds, Cold forming molds, Steam forming molds, Foaming molds, Vacuum forming molds, and Insert molding molds. We have all facilities from design to testing trial.We have Hydraulic presses, Oven, oil boiler, Steam boiler, Vacuum pump,

We have all facilities from design to testing trial.We have Hydraulic presses, Oven, oil boiler, Steam boiler, Vacuum pump,  After completing the mold, we can supply up to 100 pieces of PROTO products and mass production products.

After completing the mold, we can supply up to 100 pieces of PROTO products and mass production products.   |

|---|

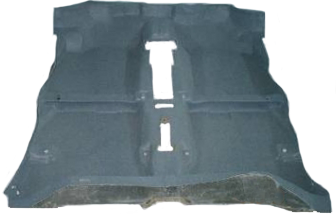

| Part name |

Carpet | Part Material |

LATEX, H/LAYER, PU FOAM |

|---|---|---|---|

| Method | Compression Forming / Trimming & Piercing | Mold Material |

AC4C / FC30 + HMD-1 |

| Machine | Press 50 / 200 ton | Lead- time |

30 ~ 90 days |

| Note | |||

|

|---|

| Part name |

Head Lining | Part Material |

PET, PUR-GF, ABS-GF |

|---|---|---|---|

| Method | Compression Forming / Trimming & Piercing | Mold Material |

AC4C / FC30 + HMD-1 |

| Machine | Press 50 / 200 ton | Lead- time |

30 ~ 70 days |

| Note | |||

|

|---|

| Part name |

Sun Shade | Part Material |

Wall paper + Azdel (PP+Glass Wool) |

|---|---|---|---|

| Method | Compression Forming & Pinching & Trimming & Piercing | Mold Material |

FC30 + KP-4 |

| Machine | Press 200 ton | Lead- time |

50 ~ 70 days |

| Note | |||

|

|---|

| Part name |

Package Tray | Part Material |

Wall Paper, Wood Stock |

|---|---|---|---|

| Method | Compression Forming & Trimming / Piercing | Mold Material |

FC30 + KP1 |

| Machine | Press 200 ton | Lead- time |

40 ~ 60 days |

| Note | |||

|

|---|

| Part name |

Parcel Shelf | Part Material |

Wallpaper + Wood Stock |

|---|---|---|---|

| Method | Compression Forming & Trimming & Piercing | Mold Material |

FC30 + KP-1 |

| Machine | Press 200 ton | Lead- time |

60 days |

| Note | |||

|

|---|

| Part name |

Door Trim | Part Material |

Woodstock, Etc. |

|---|---|---|---|

| Method | Compression Forming / Trimming & Piercing | Mold Material |

KP-1 / FC30 + HMD1 |

| Machine | Press 100 / 150 ton | Lead- time |

40 ~ 60 days |

| Note | |||

|

|---|

| Part name |

Insulator Dash Inner | Part Material |

Heavy Layer + PU Foam, PET |

|---|---|---|---|

| Method | Compression Hot Forming / Trimming & Piercing | Mold Material |

KP-1 / FC30 + HMD1 |

| Machine | Press 100 / 250 ton | Lead- time |

45 ~ 95 days |

| Note | |||

|

|---|

| Part name |

Trunk Lid | Part Material |

Wall paper + PP, PET |

|---|---|---|---|

| Method | Compression Forming / Trimming & Piercing | Mold Material |

AC4C / FC30 + HMD1 |

| Machine | Press 20 / 200 ton | Lead- time |

30 ~ 60 days |

| Note | |||

|

|---|

| Part name |

Trunk Side Trim | Part Material |

Wall Paper + PP, PET |

|---|---|---|---|

| Method | Compression Forming / Trimming & Piercing | Mold Material |

AC4C / FC30 + HMD1 |

| Machine | Press 30 / 150 ton | Lead- time |

30 ~ 60 days |

| Note | |||

|

|---|

| Part name |

Trunk Board Trim | Part Material |

Wall Paper, Wood Stock |

|---|---|---|---|

| Method | Compression Forming & Trimming & Piercing | Mold Material |

SM45C / HMD-1 |

| Machine | Press 200 ton | Lead- time |

50 ~ 70 days |

| Note | |||

|

|---|

| Part name |

Luggage Board | Part Material |

Wall Paper + Wood Stock, PP + Glass Fiber |

|---|---|---|---|

| Method | Compression Forming | Mold Material |

KP-1 |

| Machine | Press 250 ton | Lead- time |

50 ~ 70 days |

| Note | |||

|

|---|

| Part name |

Insulator Hood | Part Material |

Wall Paper + Resin Felt, PU Foam, Glass Wool |

|---|---|---|---|

| Method | Compression Hot Forming & Pinching / Trimming & Piercing | Mold Material |

KP-1 / FC30 + HMD1 |

| Machine | Press 200 ton | Lead- time |

30 ~ 60 days |

| Note | |||

|

|---|

| Part name |

Insulator Dash Outer | Part Material |

Wall Paper + Resin Felt, Glass Wool |

|---|---|---|---|

| Method | Compression Hot Forming / Trimming & Piercing | Mold Material |

KP-1 / FC30 + FCD55 |

| Machine | Press 150 / 200 ton | Lead- time |

45 ~ 60 days |

| Note | |||

|

|---|

| Part name |

Battery Cover | Part Material |

Wall Paper + PU Foam, Glass Wool |

|---|---|---|---|

| Method | Compression Hot Forming & Pinching / Cooling | Mold Material |

KP-1 / AC4C |

| Machine | Press 200 ton | Lead- time |

30 ~ 50 days |

| Note | |||

|

|---|

| Part name |

Engine Under Cover Shied | Part Material |

Wall Paper + Natural Fiber |

|---|---|---|---|

| Method | Compression Forming / Trimming & Piercing | Mold Material |

AC4C / FC30 + HMD1 |

| Machine | Press 50 / 200 ton | Lead- time |

30 ~ 60 days |

| Note | |||

|

|---|

| Part name |

Wheel Arch Liner | Part Material |

PET |

|---|---|---|---|

| Method | Compression Forming / Trimming & Piercing | Mold Material |

AC4C / FC30 + HMD1 |

| Machine | Press 50 / 250 ton | Lead- time |

30 ~ 90 days |

| Note | |||

| IMAGENO IMAGE |

|---|

| Part name |

Engine Cover | Part Material |

Wall paper, LWF, PU |

|---|---|---|---|

| Method | Compression Hot Forming & Pinching / Trimming & Piercing | Mold Material |

KP-1 / FC30 + HMD-1 |

| Machine | Press 200 ton | Lead- time |

30 ~ 70 days |

| Note | |||

Company Name : DONG-A ENG Co., Ltd. Address : 46, Emtibeui 25-ro 20beon-gil, Siheung-si, Gyeonggi-do, South Korea

TEL : 031-492-5237 FAX : 031-492-5251 Email : sales@dongaeng.co.kr

COPYRIGHT(C) 2020 DONG-A ENG CO., LTD. ALL RIGHTS RESERVED.